Supplying Casing & Tubing Equipment Covering All Sizes From 2 3/8" to 20"

Inspection and Certification of Well Control Equipment

PETROTESTING provides comprehensive services to inspect and certify well control equipment in accordance with customer SOW and API standards. Our 180 m2 testing workshop is equipped with advanced machinery and tools to perform tests in safe conditions up to 15,000 PSI.

Gate Valve Services

We specialize in the testing, repair, maintenance, and greasing of API 6A gate valves. As a leading company in gate valve repair and recertification in Algeria, our technicians are extensively trained in:

- Valve shop repair

- Valve testing and certification

- Valve groove repair and machining

- Valve greasing

BOP Repair and Recertification

Our Blowout Preventer (BOP) recertification services are meticulously designed to mitigate risks associated with equipment use and disuse. Adhering to API STANDARDS (API 53 and API 16AR), we ensure your equipment meets industry requirements. Our process includes:

- Complete tear down

- Dimensional inspection

- Hardness testing

- Positive Material Identification (PMI)

- Data book preparation approved by the OEM

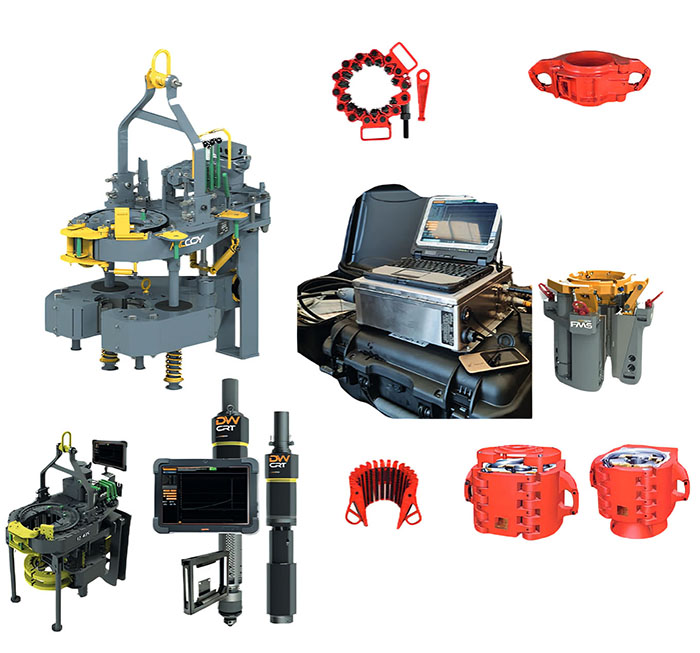

Tubular Running Services (TRS)

PETROTESTING delivers a comprehensive range of Tubular Running Services (TRS), ensuring safe, efficient, and precise handling of tubular goods for the oil and gas industry. Our advanced technology and expert team are equipped to handle even the most complex operations, including specialized handling of chrome pipe. Our services and equipment include:

Hydraulic Power Tongs:

Precision-engineered tools for the secure make-up and break-out of tubular connections, with a focus on protecting chrome pipe and other sensitive materials.

Torque Monitoring Systems:

Real-time torque and rotation monitoring to ensure the safe and precise make-up of tubular connections, vital for chrome and premium materials.

Tubular Handling Tools:

Designed for safe and efficient lifting, rotating, and positioning of tubulars with minimal risk of damage.

Casing Running Tools (CRT):

High-performance tools that provide control during casing running operations, tailored for chrome and standard pipes.

Hydraulic Elevators and Slips:

Automated systems that increase operational safety and efficiency, particularly for chrome installations.

Bucking Services:

Precision make-up and break-out of threaded connections, ensuring the integrity and performance of chrome and standard tubulars before deployment.

Pick-up/Lay-down Machines:

Efficient machines for safe handling and transportation of tubulars, including chrome pipe, reducing the risk of damage and improving operational speed.

Fill-up Tools and Casing Cutter Machine:

Fill-up Tools: Tools designed for quick, safe filling of chrome and other tubulars during running-in-hole operations, reducing downtime and enhancing safety.

Casing Cutter Machine: Our casing cutter machine offers precise and efficient cutting of casing strings, allowing for safe and controlled removal during well intervention or plug and abandonment operations.

PETROTESTING provides comprehensive solutions that streamline operations and maximize safety, particularly in handling chrome pipe and other specialized materials. With our state-of-the-art equipment and dedicated team, we ensure your projects are completed on time and with exceptional precision.

Quality Assurance

All services are performed with strict adherence to API standards, ensuring your equipment's reliability, safety, and long-term performance.